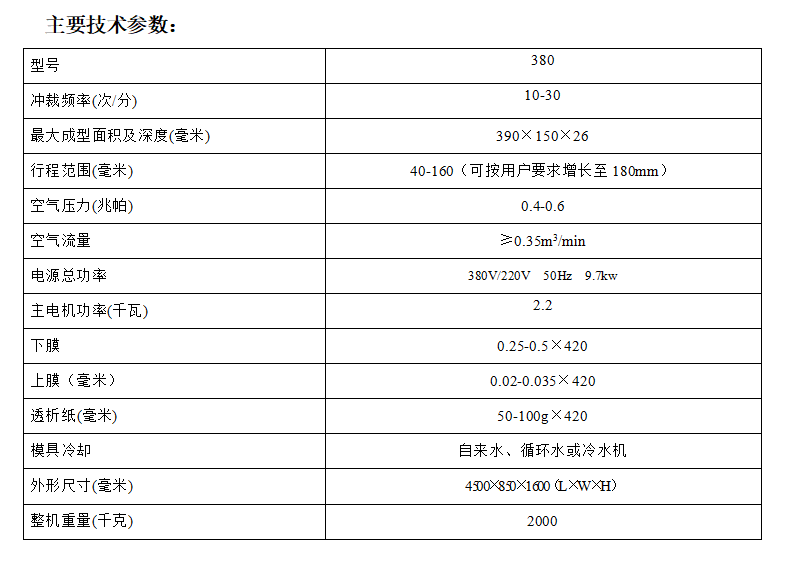

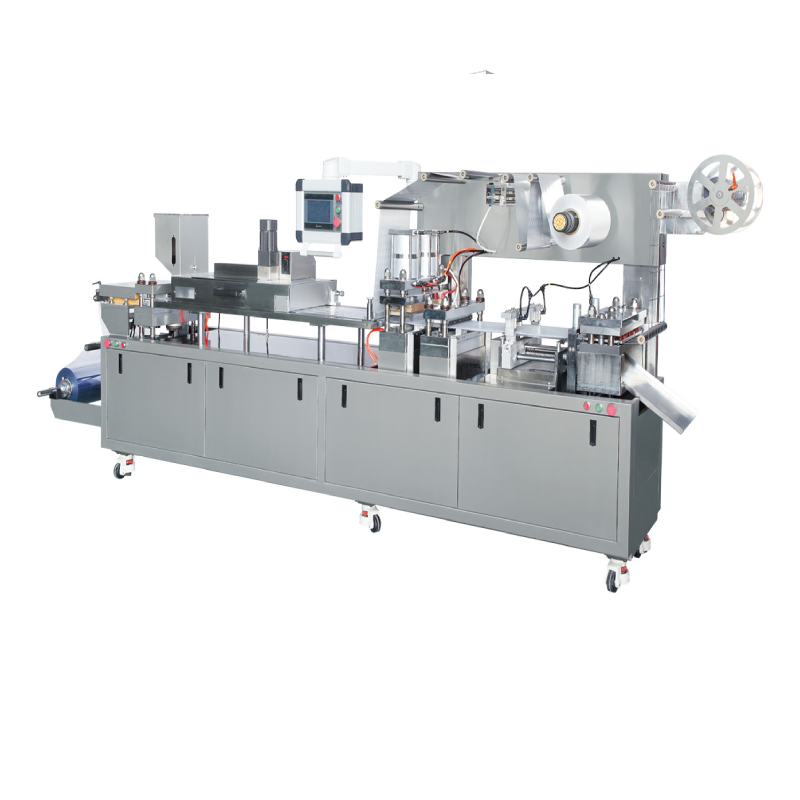

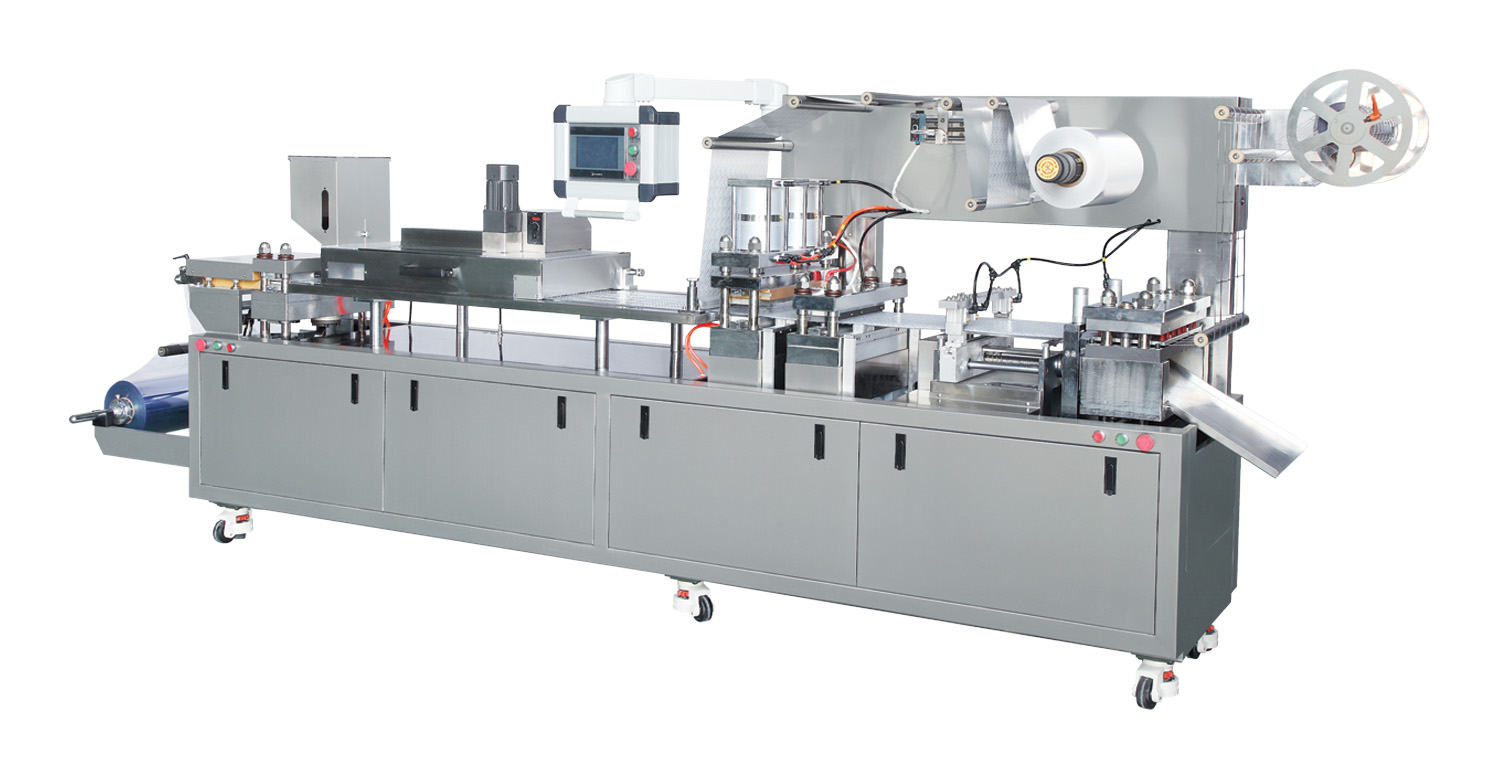

pastespackaging machine

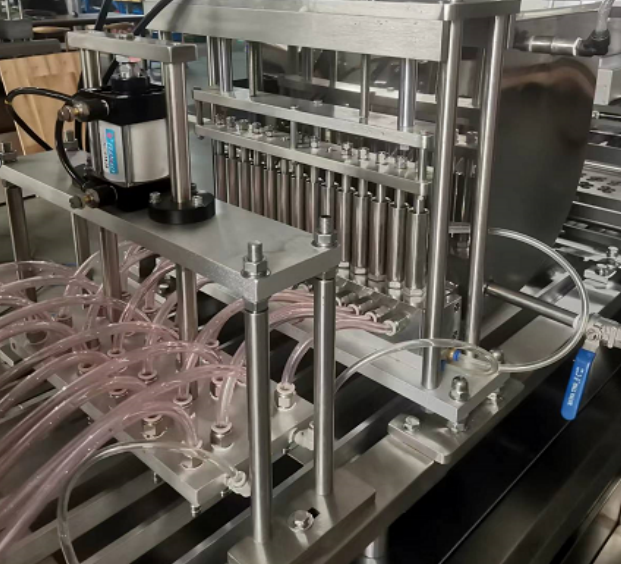

Paste doser

Product Description:

This machine is for coil material PP material, pvc material, PET material, etc. Automatic molding after canning products. According to the product selection of automatic feeding, can also be manually feeding, the machine automatically laminating heat sealing molding, cutting finished products. The machine adopts PLC programming, frequency conversion speed control and human-machine interface operation. It is full-featured, easy to operate, stable and reliable, and meets the requirements of GMP specification. Due to the large molding area of the machine, a blanking section, to a certain extent, to meet the needs of large-scale production of enterprises, suitable for the food industry, pharmaceutical industry and so on.

Features:

1, molding, heat sealing, batch marking, creasing, punching and cutting devices are all made of rack and pinion positioning of the mandrel, shaking the handle, all kinds of devices can be easily and freely moved on the mandrel, and can be quickly corrected and positioned according to the ruler and the fastening nut.

2、Manipulator traction with adjustable stroke can adapt to the packaging of various sizes of sections. Without changing the cam lift, double traction pendulum is used to lengthen the traction stroke.

3、Heating to the plate, positive pressure molding, upper and lower anilox, cylinder heat sealing, automatic feeding, automatic indentation and batch numbering, automatic punching and cutting of the plate, easy to operate.

4, Positive pressure molding coupled with the configuration of mechanical punch, to ensure that the blister molding uniform. It can be adapted to the medical industry, food industry and a wide range of packaging.

5、Main transmission part adopts parallel shaft helical gear reducer, running smoothly. Forming, heat sealing, creasing and other molds use Shaw nail positioning, pressure plate fastening, accurate positioning, easy to change the mold, saving package material.